• Standard-Sized Sample Compartment in a Compact Bench

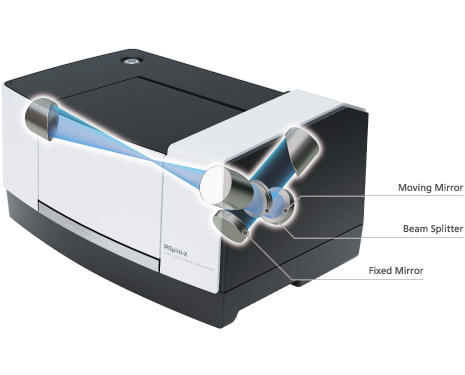

IRSpirit-X Series

IRSpirit, Ready to Run

IRSpirit FTIR spectrophotometers are extremely compact, but can still be used with standard accessories from Shimadzu and other manufacturers.

IRSpirit instruments come with IR Pilot software, which offers 23 application programs without the need for parameter setup. Measure multiple samples with just a few clicks.

You can choose from the highly sensitive IRSpirit-TX, the affordable IRSpirit-LX, and the highly reliable IRSpirit-ZX with its moisture-resistant design.

IRSpirit, IR Pilot, IRXross, IRTracer, LabSolutions, QATR, EDXIR-Holder, EDXIR-Analysis, Analytical Intelligence logo, and eco mark are trademarks of Shimadzu Corporation or its affiliated companies in Japan and/or other countries.

Značajke

-

• Great for Small Lab Spaces

• Standard-Sized Sample Compartment in a Compact Bench -

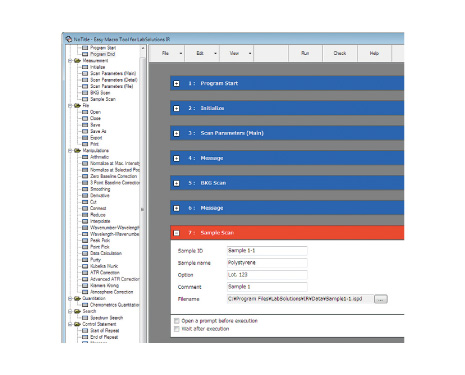

• IR Pilot™ Pre-built Macro Program

• Spectrum Advisor Function

• Contaminant Analysis Program

• Identification Test Program -

• Technology Inherited from Higher-End Models

• Reliable Parts Come with a 10-Year Warranty

Note: There is an additional work fee for replacing parts.

• High Durability Due to Humidity-Resistant Design

• Internal Dehumidifier (Optional) Ensures Robustness

• Instrument Status Monitoring -

• Easy Macro – Just a Single Click Launches Routine Work

-

Videos

-

IR Pilot Identification Test Program

This program makes pass/fail judgments for test samples based on verification methods described in Pharmacopoeia and standards specified in each country, such as "Infrared Spectrophotometry" in the Japanese Pharmacopoeia and Japan's Specifications and Standards for Food Additives. In addition to identification tests for pharmaceutical and food product identification tests, the program can also be used for acceptance and pre-shipment inspections.

*The operating procedures are the same for IRSpirit-X. -

IR Pilot Contaminant Analysis Program

The contaminant analysis program identifies measured contaminants using Shimadzu's proprietary identification algorithm (Japanese Patent No. 5205918) in combination with a spectral library containing more than 550 spectra for substances commonly detected as contaminants. After data analysis, it automatically makes a pass/fail judgment and creates a report. Even if the contaminant is a mixture, it searches for major and minor components and displays their ranks.

*The operating procedures are the same for IRSpirit-X. -

IRSpirit-X Series Fourier Transform Infrared Spectrophotometer

IRSpirit FTIR spectrophotometers are extremely compact, but can still be used with standard accessories from Shimadzu and other manufacturers. IRSpirit instruments come with IR Pilot software, which offers 23 application programs without the need for parameter setup. Measure multiple samples with just a few clicks. You can choose from the highly sensitive IRSpirit-TX, the affordable IRSpirit-LX, and the highly reliable IRSpirit-ZX with its moisture-resistant design.